Many believe the transition from impact to insight happens within a second using the Schmidt or rebound hammer. However, this may not be entirely true since the results from the instrument still need to be converted to obtain actual compressive strength values. This article sheds light on this process.

Compressive strength is vital for structural integrity, especially for construction materials like concrete, as a building’s safety, longevity, and durability depend on its compressive strength. Traditionally, assessing compressive strength required destructive testing methods that could compromise the structure’s integrity. However, the Schmidt hammer method offers a non-invasive approach to estimating compressive strength, making it the most widely used instrument for non-destructive testing today.

How Does the Schmidt Hammer Work?

Simply put, the Schmidt hammer is a device that can read the secrets hidden within a structural element or material’s surface to reveal its hardness or inner strength. It indirectly measures in-situ compressive strength by using established correlations and conversion factors.

This handheld device operates on a simple yet profound principle. It uses an impact plunger or spring-loaded mass to strike a material’s surface, measuring the rebound velocity to provide valuable information about hardness or strength. Find below the breakdown of this widely used method in construction, quality control, and structural assessments to ensure the safety and reliability of structures:

1. Spring-Loaded Mass: The Schmidt hammer has a cylindrical body with a hardened steel hammerhead at one end. Inside the body, there is a spring-loaded mass connected to the hammerhead. This mass can slide freely within the body.

2. Impact: To perform a test, the operator places the Schmidt hammer’s impact plunger against the material’s surface that needs testing. The plunger is usually flat and has a smooth surface to ensure proper contact.

3. Release and Impact: The operator releases the hammer, allowing the spring-loaded mass to strike the material’s surface with a defined and consistent impact force. The impact force varies depending on the specific Schmidt hammer model but is standardized for each model.

4. Rebound: Upon impact, the mass rebounds from the surface. The rebound distance or velocity is directly related to the hardness or compressive strength of the material. Softer materials will cause the mass to rebound with less velocity or shorter distance, while harder materials will result in higher rebound velocities or longer rebound distances.

5. Reading: The Schmidt hammer has a scale that measures and displays the rebound value. This value is typically recorded as a numerical index. Higher rebound values correspond to stronger and more durable materials, while lower values indicate weaker and less durable materials.

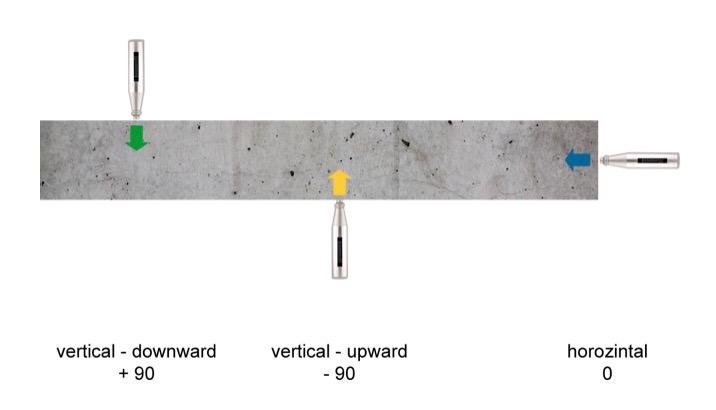

Direction of Use

Paying attention to the direction in which you take measurements when using a Schmidt hammer is vital. There are three possible directions, namely vertical downward, vertical upward, and horizontal. The choice of direction depends on the specific application and the orientation of the material being tested. It is essential to follow the appropriate testing procedure and take measurements in the direction that accurately represents the load-bearing orientation of the material. Let’s take a closer look at each direction:

1. Vertical Downward Direction: Hold the Schmidt hammer vertically with the plunger pointed downwards in this direction. This direction is commonly used to assess the compressive strength of concrete or other materials in a vertical orientation, such as concrete floors, walls, beams, and columns.

2. Vertical Upward Direction: Hold the Schmidt hammer vertically with the plunger pointing upward. This direction is useful when assessing the compressive strength of overhead structures, ceilings, or any material that needs to be tested from below.

3. Horizontal Direction: Hold the Schmidt hammer horizontally, parallel to the surface being tested in this case. This direction is often used to determine the compressive strength of surfaces that cannot be easily accessed from above or below, such as horizontal slabs, beams, bridge decks, or pavements.

Compressive Strength Calculation

It is ideal to take between six (6) to ten (10) readings from a test area to ensure accurate results. The impact points should be spaced at a minimum distance of 25mm and not less than 50mm from the edges of the material being tested.

For instance, let’s assume these ten (10) readings from a column: 24, 26, 26, 33, 25, 27, 26, 26, 25, 24. To calculate the average, add all the readings and divide the sum by 10. In this case, the average rebound number is 26.

To improve the accuracy of the rebound number, exclude readings that are six (6) units more or less than the average calculated. The upper limit is 26 + 6 = 32, and the lower limit is 26 – 6 = 20. Therefore, eliminate 33 from the readings and calculate the new average rebound number as 25.44. Let’s say 25.

Note that a set of ten readings should not have more than two (2) outliers, preferably one at each end. If you have more than two outliers, discard the readings and retest.

So, what’s left? Refer to the vertical downward curve to determine the corresponding compressive strength value for a rebound number of 25. Ensure to use the “Type A” direction and the cube curve. According to the curve, the corresponding compressive strength value should be approximately 20.7 N/mm².

Wrap Up

The Schmidt hammer is a tool commonly used on-site to estimate the compressive strength of materials. It has numerous advantages, such as being fast, practical, adaptable, cost-effective, and minimally disruptive. It also provides reliable results, with an accuracy rate of over 90%. However, it is vital to note that the Schmidt hammer method has some limitations.

Factors like surface condition, scale calibration, material heterogeneity, and operator technique can all affect the results. Therefore, use the Schmidt hammer with other testing methods and calibrate the scale based on specific material properties and local conditions. This multi-faceted approach ensures a more precise evaluation of structural elements.

Follow me on LinkedIn for more interesting and educating engineering posts.

Have you visited our bookstore today? 🥰

Click here to preview the book

Click here to preview the book

Thank you for visiting C-E Channel today.

It is an honour to have you 🤭

2 replies on “Estimating Compressive Strength from Schmidt Hammer NDT Results”

Thank you Kolade for this wonderful expository on the use of Schmidt rebound hammer.

I hope to get more engaging content from your blog

LikeLiked by 1 person

Thank you for commenting. I am glad you liked the article.

LikeLike